Umkhiqizo omuhle awucutshungulwa kuphela, kodwa futhi udinga ukwelashwa okuhlukahlukene kwendawo ukuze uzuze ukumelana nokugqwala, ukumelana nokugqokwa, ubuhle, kanye nokwandisa impilo yesevisi.I-RCT MFG inesipiliyoni seminyaka eminingi ekucubunguleni i-CNC kanye nokucubungula ukubumba umjovo, futhi ihlinzeka ngochungechunge lwezinsizakalo ukusuka ekucutshungulweni kuya ekuphathweni komhlaba kuya ekuhlanganisweni.Ngakho-ke, ngaphezu kobuchwepheshe bokwenza izinto, ibuye ibe nolwazi olucebile ekwelapheni okungaphezulu.Izinqubo ezikhona zokwelapha ezikhona zihlanganisa: ukudweba, upende wokubhaka, ukumbozwa kwempushana, ukuqhunyiswa kwesihlabathi, ukuqhunyiswa kwesibhamu, i-anodizing, i-anodizing yefilimu ewugqinsi, i-micro-arc anodizing, i-electroplating, i-electrophoresis, i-laser eqoshiwe, ukuphrinta kwesikrini sikasilika, insimbi exutshwe, ukupholisha isibuko, ukudaya, ukumnyama, iphethini ye-CD, i-etching, isicwebezelisi esiphezulu, iphethini ye-etch, i-Epoxy, njll., isiza ukwenza imikhiqizo yakho ibe sezingeni eliphezulu.

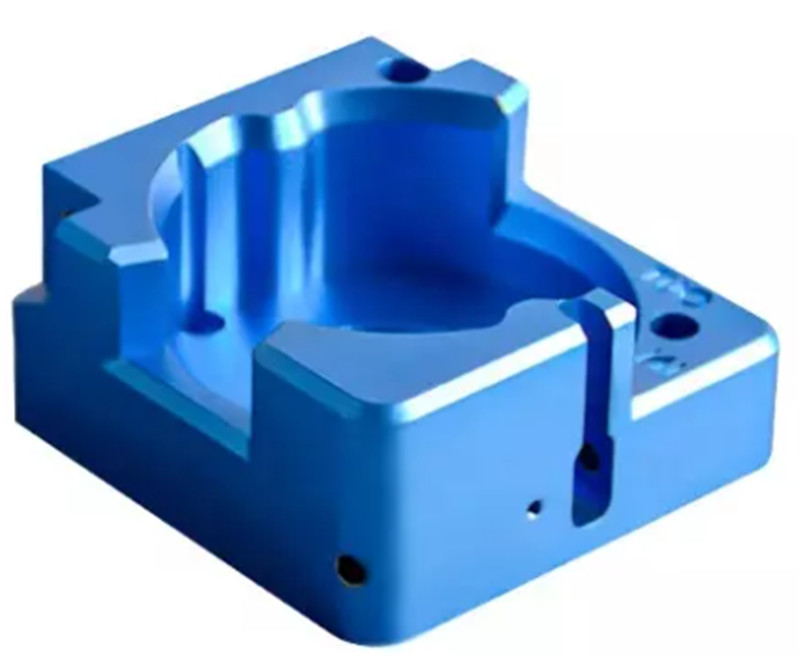

I-anodizing

Kuyinqubo ye-electrolytic oxidation, eguqula ingaphezulu lezinto ezibonakalayo zibe ifilimu evikelayo, okwenza kube nzima ukukhipha i-oxidize nokugqwala, okunweba impilo nokufeza ukubukeka kwemibala ehlukahlukene.Izindlela zokwelapha ezisetshenziswa kakhulu ze-anodizing zihlukaniswe zibe: i-anodizing evamile , i-anodizing yensimbi exutshwe, i-anodizing eqinile, i-anodizing yefilimu ewugqinsi, i-micro-arc oxidation, njll. Izinto ezingase zenziwe nge-oxidized yilezi: i-aluminium alloy, i-magnesium alloy, i-titanium alloy, njll.

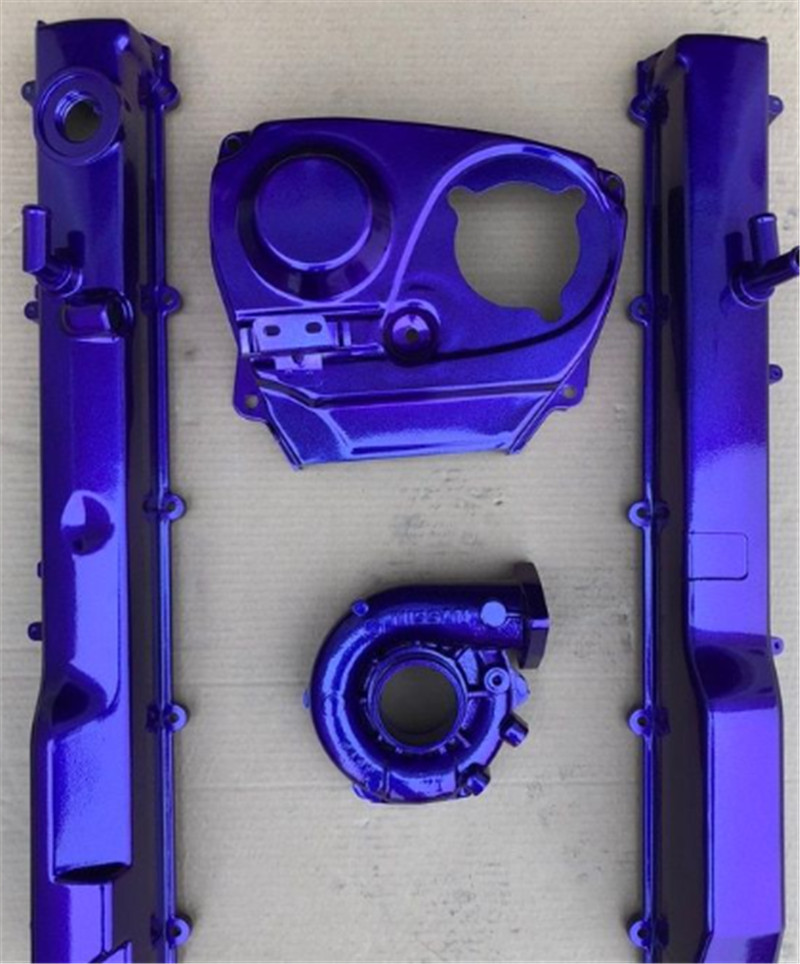

I-Electroplating

Inqubo eyisisekelo ye-electroplating iwukucwilisa ingxenye esixazululweni sikasawoti wensimbi njenge-cathode, kanye nepuleti lensimbi njenge-anode, futhi udlulise okwamanje ukuze ufake i-coating oyifunayo engxenyeni.Umphumela ofanelekile we-electroplating uzokwenza umkhiqizo wakho ube yimfashini ephezulu kakhulu futhi nawo.Emakethe engcono, i-electroplating evamile ihlanganisa i-copper plating, i-nickel plating, i-silver plating, i-golden plating, i-chrome plating, i-galvanizing, i-tin plating, i-vacuum plating, njll.

I-Electrophoretic coating

Ngokuthuthuka okuqhubekayo kwesidingo sezimboni, ubuchwepheshe bokuhlanganisa i-Electrophoretic bungenza ngezifiso imibala ehlukahlukene, bugcine ukucwebezela kwensimbi futhi buthuthukise ukumelana nokugqwala kwendawo, okunomthelela omncane ekunembeni komkhiqizo.Ubukhulu bungaba ngu-10-25um, kanti obukhulu kakhulu bungenziwa ngezifiso

Passivation

I-Passivation, eyaziwa nangokuthi ukwelashwa kwe-chromate, inqubo yokukhetha esusa amafutha angaphezulu, ukugqwala, nama-oxides ngokucwiliswa noma ukuhlanzwa nge-ultrasonic.Ngokusabela kwamakhemikhali kwesisombululo se-passivation, kungavimbela ukugqwala futhi kwandise ukugqwala.Umbala wefilimu ye-passivation uzoshintsha ngezinto ezahlukene.I-passivation ngeke ikhulise ubukhulu bomkhiqizo, futhi asikho isidingo sokukhathazeka ngokuthi ithinta ukunemba komkhiqizo.

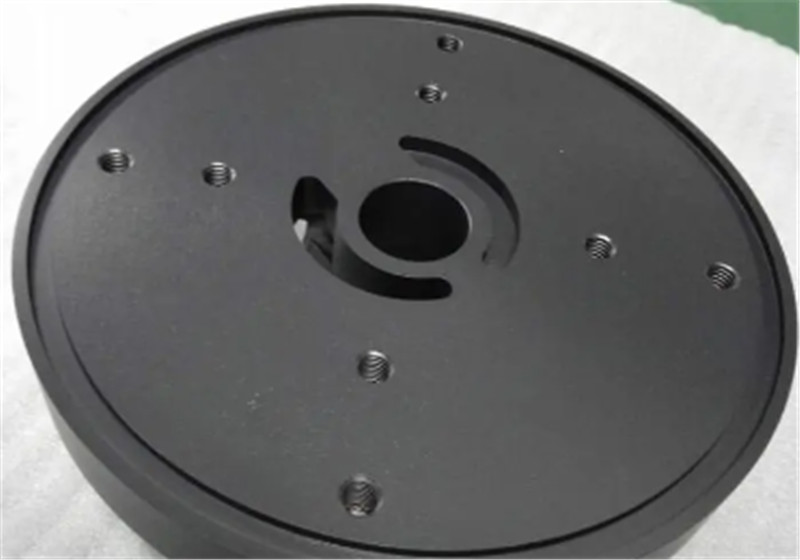

Imnyama

Ubumnyama bubizwa nangokuthi i-bluing.Isimiso ukucwilisa umkhiqizo kusisombululo samakhemikhali esinamandla oxidizing ukuze wenze ifilimu ye-oxide endaweni yensimbi ukuze uhlukanise umoya futhi ufeze injongo yokuvimbela ukugqwala.Le nqubo iyasebenza ezintweni zensimbi.

I-QPQ (Quench-Polish-Quench)

Kubhekiselwa ekubekeni izingxenye zensimbi ezinensimbi ezinhlotsheni ezimbili zamabhavu kasawoti anezici ezihlukene, kanye nokufaka izakhi ezihlukahlukene endaweni yensimbi ukuze zakhe ungqimba oluyinhlanganisela lokungenisa, ukuze kufezwe injongo yokuguqula ingaphezulu lezingxenye.Inokumelana nokugqokwa okuhle, ukumelana nokukhathala, ukumelana nokugqwala kanye nokuguqulwa okuncane.Le nqubo isebenza kuzo zonke izinto zensimbi.

(Qaphela: Imikhiqizo yensimbi engagqwali ayikwazi ukwenziwa mnyama, futhi indawo engaphezulu ingaba mnyama yi-QPQ)

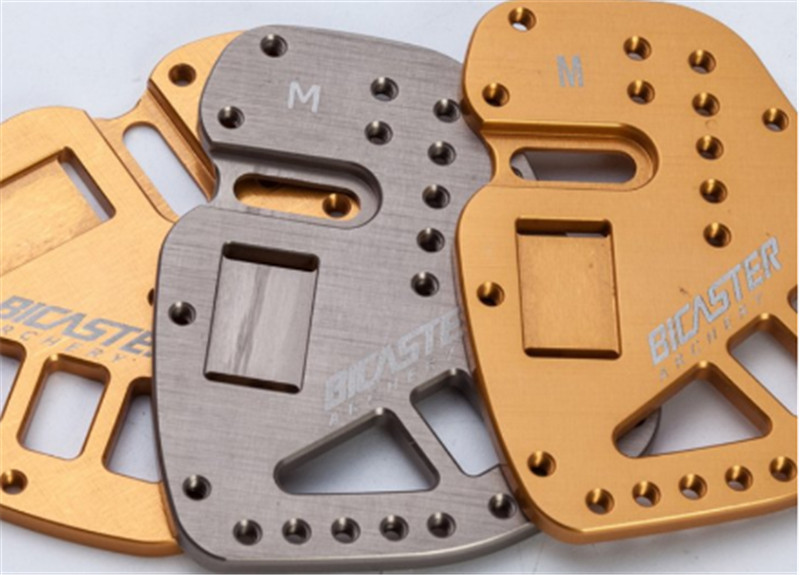

Laser engraving

Ukudweba nge-laser, okubuye kubizwe ngokumaka nge-laser, kuyinqubo yokwelapha engaphezulu kusetshenziswa imigomo yokubona ukwenza i-LOGO noma amaphethini emikhiqizweni.Umphumela wokuqoshwa kwe-laser unomphela, izinga eliphezulu liphezulu, futhi lifanele imikhiqizo eyenziwe ngezinto ezihlukahlukene zensimbi nezepulasitiki.

Ukuphrinta kwesikrini sikasilika

Ukuphrinta kwesikrini sikasilika kusho ukuthi uyinki udlulisela iphethini emkhiqizweni ngesikrini.Umbala we-inki ungenziwa ngokwezifiso ngokuya ngezidingo zamakhasimende.I-RCT MFG yenze imibala engu-6 emkhiqizweni ofanayo, ohlanganisa omnyama, obomvu, oluhlaza okwesibhakabhaka, ophuzi nomhlophe.,okuhlaza.Uma ufuna ukuthi umphumela wokuphrinta isikrini sikasilika uhlale isikhathi eside, ungakwazi futhi ukwengeza ungqimba lwe-UV ngemva kokuphrinta kwesikrini sikasilika ukuze welule ukuphila kwayo.Ukuphrinta kwesikrini sikasilika kulungele izinto ezihlukahlukene zensimbi nepulasitiki, futhi kungahlanganiswa nokwelashwa okungaphezulu okufana ne-oxidation, ukudweba, ukufutha ngempushana, i-electroplating, ne-electrophoresis.

Ukupholisha

Ukupholisha ukwenza umkhiqizo ube muhle, ukhanye futhi uvikele indawo engaphezulu.Ukupholisha nokuba sobala kuyisinqumo esihle kuwe.Ukupholishwa kwemikhiqizo yehadiwe kuhlukaniswe ngokupholisha ngesandla, ukupholisha ngomshini, nokupholisha nge-electrolytic.Ukupholisha nge-electrolytic kungasetshenziswa ukufaka esikhundleni sokupholisha kwemishini esindayo, ikakhulukazi ezingxenyeni ezinobumo obuyinkimbinkimbi nezingxenye okunzima ukuzicubungula ngokupholisha okwenziwa ngesandla kanye nezindlela zemishini.I-Electrolytic polishing ivame ukusetshenziselwa insimbi, i-aluminium, ithusi nezinye izingxenye.

Insimbi Exutshiwe

Insimbi exutshiwe iyindlela yokwelapha engaphezulu eyenza imigqa phezu kwendawo yokusebenza ngokusebenzisa ibhande elicindezelwe eliyisicaba kanye nebhulashi lerola elingalukiwe ukuze kuzuzwe umphumela wokuhlobisa.Ukwelashwa okuxutshiwe kungabonisa ukuthungwa kwezinto zensimbi, futhi kuya ngokuya kudume kakhulu empilweni yanamuhla.Isetshenziswa kakhulu kumaselula, amakhompyutha, iziqapha, ifenisha, izinto zikagesi kanye namanye amagobolondo.

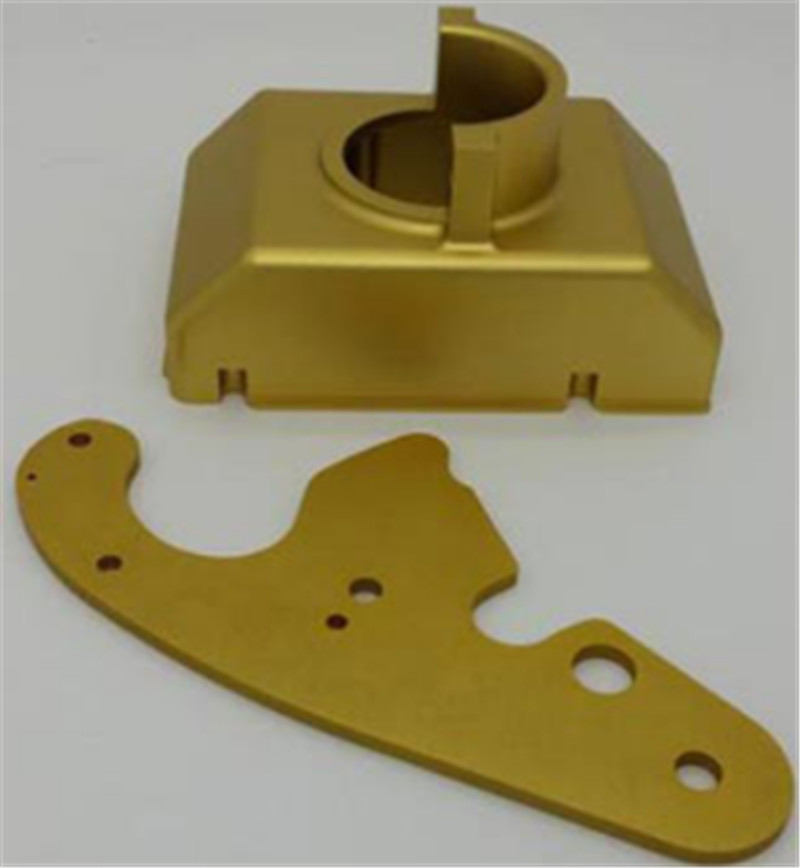

Ukufafaza ngopende kanye nokufutha ngempushana

Ukufafaza ngopende kanye nokufutha ngempushana kuyizindlela ezimbili zokwelapha ezivamile ezingaphezulu ezingxenyeni zehadiwe ezifafazwayo, futhi ziyindlela yokwelapha yangaphezulu esetshenziswa kakhulu ukuze uthole izingxenye ezinembayo kanye nokwenza ngokwezifiso iqoqo elincane.Bangakwazi ukuvikela ubuso ekugqwaleni, ukugqwala, futhi bangazuza nomphumela wobuhle.Kokubili ukufutha ngempushana nokudweba kungenziwa ngendlela oyifisayo ngendlela yokwenza ngendlela ehlukene (imigqa emihle, imigqa emagebhugebhu, imigqa yesikhumba, njll.), imibala ehlukene, namazinga ahlukene e-gloss (i-matte, flat, high-gloss).

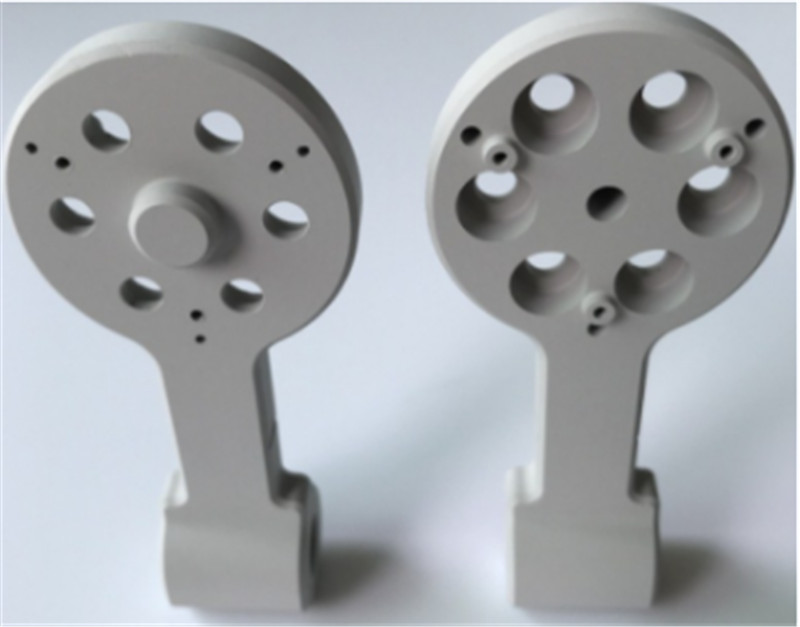

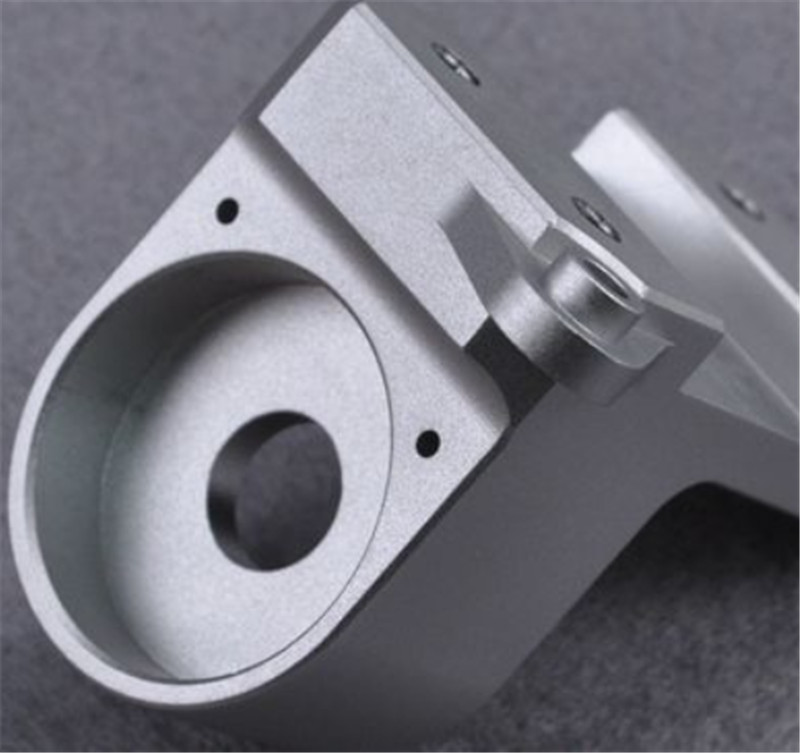

Ukuqhunyiswa kwesihlabathi

I-Sandblasting ingenye yezindlela zokwelapha ezivame ukusetshenziswa endaweni yemikhiqizo yehadiwe.Ingathuthukisa ukuhlanzeka kanye nokuqina, futhi ikhulise ukunamathela nokuqina phakathi komkhiqizo kanye nokumbozwa.Ngakho-ke, izindlela eziningi zokwelapha ezingaphezulu zikhetha i-sandblasting njengokwelashwa kwazo kwangaphambili.Okufana: i-sandblasting + oxidation, sandblasting + electroplating, sandblasting + electrophoresis, sandblasting + dusting, sandblasting + paint, sandblasting + passivation, njll.

I-Teflon yokufafaza

Okubizwa nangokuthi i-Teflon spraying, iyindlela yokwelapha ehlukile kakhulu.Inezici eziphakeme ze-anti viscosity, i-non viscosity, ukumelana nokushisa okuphezulu, ukungqubuzana okuphansi, ukuqina okuphezulu, ukungabi manzi, kanye nokumelana namakhemikhali aphezulu.Ngakho-ke, isetshenziswa kabanzi embonini yokudla, i-tableware, i-kitchenware, imboni yephepha, imishini yezokwelapha, imikhiqizo ye-elekthronikhi nemikhiqizo yezimoto, izinto zamakhemikhali, njll.

Etching

I-Etching iyindlela yokususa izinto usebenzisa ukusabela kwamakhemikhali noma umthelela womzimba.Imvamisa kubhekiselwa ku-etching, eyaziwa nangokuthi i-photochemical etching, esho ukususa ifilimu evikelayo yendawo ezoqoshwa ngemuva kokwenziwa kwepuleti lokuchayeka nokuthuthukiswa, kanye nokuthinta isisombululo samakhemikhali ngesikhathi sokuqopha ukuze kuzuzwe umphumela wokuhlakazeka nokugqwala, okwenza umphumela i-concave-convex noma ukubumba okungenalutho.

I-IMD

In Mold Decoration (IMD) iyindlela engabizi kakhulu yokuhlobisa izingxenye zepulasitiki.Iqukethe izinyathelo ezine: Ukuphrinta, Ukubumba, Ukunquma kanye Nokubunjwa komjovo.Futhi Kuwubuchwepheshe obudumile emhlabeni jikelele bokuhlobisa indawo.Ingaphezulu liqinile futhi libonisa ifilimu, ungqimba lwephethini yokuphrinta emaphakathi, isendlalelo sokubumba umjovo wangemuva, futhi phakathi kukayinki kungenza umkhiqizo umelane nokungqubuzana., vimbela ingaphezulu ukuthi lingaklwebheki, futhi lingagcina umbala ugqamile futhi kungabi lula ukufiphala isikhathi eside.

Ukuphrinta Kwephedi

Ukuphrinta kwe-pad, okubizwa nangokuthi i-tampography noma ukuphrinta kwe-tampo, kuyinqubo yokuphrinta ye-offset engaqondile (i-gravure) lapho i-silicon pad ithatha isithombe esingu-2-D epuleti lokuphrinta eliqoshwe nge-laser (elibizwa nangokuthi i-cliché) bese lisidlulisela ku-3- D into.Ngenxa yokuphrinta kwephedi, manje sekungenzeka ukuphrinta zonke izinhlobo zemikhiqizo enomumo onzima njengegobile (i-convex), i-hollow (i-concave), i-cylindrical, i-spherical, ama-engeli ayinhlanganisela, ukwakheka, njll. ebingatholakali ngezinqubo zokuphrinta zendabuko.

Ukuphrinta kwe-transfter yamanzi

Ukuphrinta ukudluliswa kwamanzi kuwuhlobo lokuphrinta olusebenzisa ukucindezela kwamanzi ukuze kusetshenziswe i-hydrolyze iphepha lokudlulisa/ifilimu yepulasitiki enamaphethini ombala.Inqubo yezobuchwepheshe ihlanganisa ukukhiqizwa kwephepha lokunyathelisa lokudluliswa kwamanzi, ukucwiliswa kwephepha lembali, ukudluliswa kwephethini, ukomisa, nomkhiqizo ophelile.

I-conductive coating

I-conductive coating iwuhlobo lukapende olungasetshenziselwa ukufafaza.Ingakwazi ukuhambisa ugesi ngemva kokoma ukwenza ifilimu kapende, ukuze ivikele ukuphazamiseka kukazibuthe kagesi.Njengamanje, isetshenziswa emikhakheni eminingi yezimboni yezempi neyomphakathi efana ne-electronics, izinto zikagesi, ezondiza, imboni yamakhemikhali, ukuphrinta, njll.

Isikhathi sokuthumela: Apr-11-2023